The IT/OT convergence dilemma

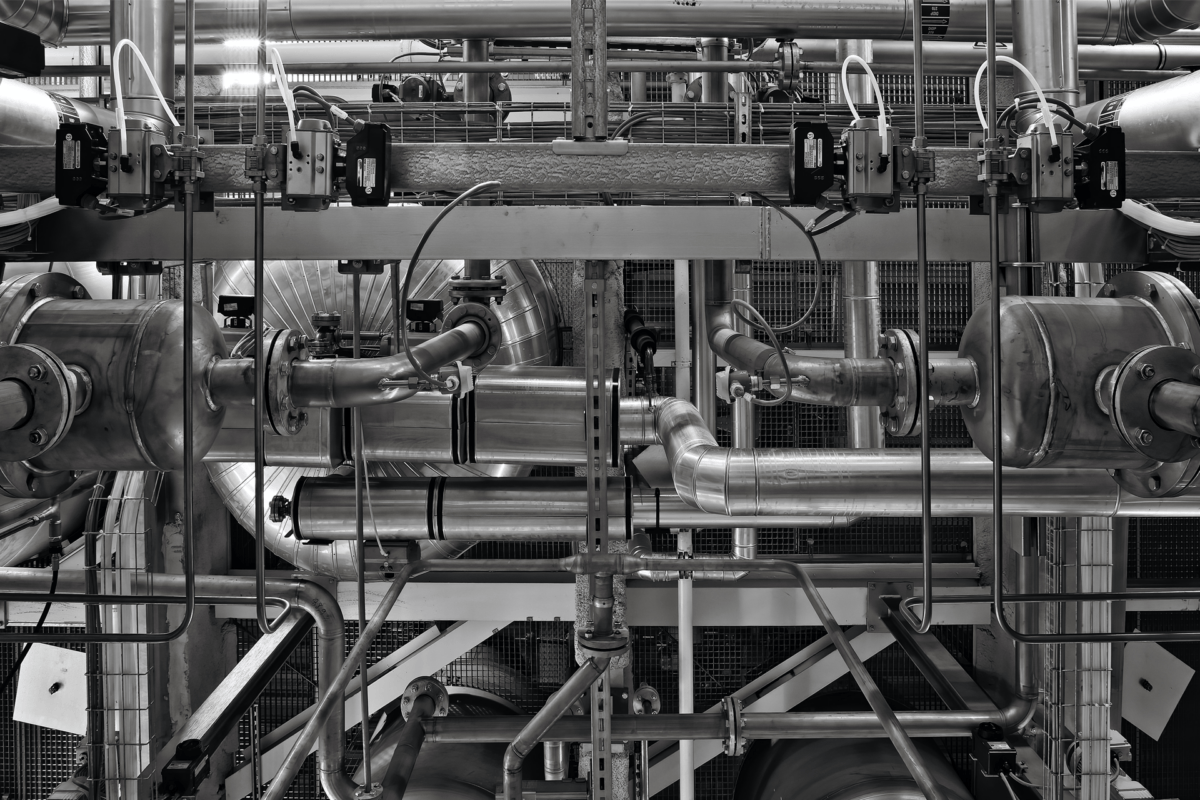

The converging of IT and OT systems, combined with increased use of IoT in industrial environments, is challenging many security practitioners in defining the best security architecture that aligns to transforming and modernizing industrial environments.

Where 15+ years ago, both IT and OT worlds could function independent from each other, today’s IT & OT systems are heavily intertwined and have dependencies with each other. This results in a significant risk of operational downtime and exponential exposure to new cyber threats.

Due to this convergence, unified visibility, operational resilience, and risk management are now key to accurate detect cyberthreats and anomalies as they happen.

What is necessary to be successful in your OT security journey?

The need for visibility – You can’t protect what you can’t see!

How many OT assets do you exactly have? A question, if asked to OT/ICS plant managers, that raises eyebrows and makes them feel a little bit uncomfortable as most of them can only give a ball park figure.

Independent of the industry you are operating in, creating an accurate asset inventory and keeping it up-to-date can be difficult and an extremely time-consuming task.

Not only do industrial networks contain a large number of devices from multiple vendors, assets are often added and changed frequently. As such, complex OT environments typically contain security and reliability blind spots you’re not even aware of.

How can spotit help?

Together with Nozomi Networks, we can automate your asset inventory creation, eliminating blind spots and revealing assets other vendors don’t see, providing you with accurate and extensive information on all OT, IoT and IT assets from all systems—no matter their age, vendor, or function.

Complete visibility over OT/ICS network traffic is a ‘must have’ in order to detect suspicious & malicious communication patterns in your OT/ICS environment.

Nozomi captures all data on the OT network making use of rapid deep packet inspection decoding and analyzing all industrial protocols.

It provides extensive node information including name, type, and firmware version and reduces risks by visualizing your OT/ICS network giving detailed insight into your OT/IoT networks including asset behavior, roles, protocols, and data flows.

The need for reliability- Operational resilience is key!

Can your OT network team differentiate normal from abnormal traffic? Do you know why an OT device starts behaving differently? Can you determine what/when was the last known good state?

Operational resilience has never been more critical nowadays. The competitive landscape within manufacturing, along with recent supply chain disruptions, puts immense pressure on factories to improve uptime.

Assessing cyber and operational risks for manufacturing facilities is of paramount importance to boards of directors. The ability to quickly detect failures or potential failures and then respond to them in real time is challenging without visibility into OT environments. Therefore, to improve operational resilience, it is essential that while factories are digitalizing, cyber and operational risks are continuously assessed and mitigated.

How can spotit help to increase reliability in your OT environment?

Improving operational reliability requires real-time situational awareness. By learning your factory’s normal network patterns and manufacturing processes, spotit & Nozomi can identify anomalies as they unfold in the network.

We help you act before equipment failure, unusual variable values or network stability issues can have an impact on the production uptime or quality.

The need for fast risk reduction – Focus on critical vulnerabilities

Does your security monitoring technology put essential information at your fingertips to speed your response to any security incidents?

Managing OT security in today’s aggressive cyberattack environment is challenging. It demands rapid action to reduce the risks faced and find approaches that recognize OT’s increasing convergence with IT components.

This rapid action boils down to the fact that in order to be successful in your OT security strategy, you need to be able to detect and collect operational and cybersecurity issues in real-time, and take corrective actions before the threat can strike your environment.

How can spotit help to identify & remediate OT risks in the fast lane?

We can give you confidence regarding the state of your OT security operations thanks to our 24/7/365 monitoring and deep OT capabilities of the Nozomi networks solution, which we can integrate into our own spotit SOC.

You are informed of cyberattacks, vulnerabilities and risks. Pinpointed alerts and actionable insights help you mitigate cyber and operational threats before they cause harm to your business. All under view of one single pane of glass, regardless of location or number of devices to be monitored.

More info?

Do you want more information what spotit can mean for your OT cybersecurity journey? Do you want to assess your current OT/IT cybersecurity architecture and see what is happening in your OT environment?